STIHL has a global presence with production facilities on four different continents. How well do you know the world of STIHL production? Test your knowledge about our production network here. Tip: If you haven’t already done so, look through my “friendship book” again.

Manufacturing family

STIHL is a large international family with 44 STIHL-owned sales and marketing companies, approximately 120 importers, and more than 52,000 dealers in over 160 countries. The company manufactures products and components in Germany as well as the USA, Brazil, Switzerland, Romania, Austria, China, and the Philippines. Get to know the STIHL manufacturing network in a very special “friendship book”.

Explore our locations:

STIHL Manufacturing Friends

How well do you know our production sites? Find out if you’re a real friend of STIHL.

Since 2023 my Plant 1 has been enhanced by STIHL Brand World, in which you can experience every facet of me.

Germany

This is me: The head office in Germany, hallöle!

Year of birth: 1926.

Place of birth: Stuttgart City.

I live here: In Waiblingen with no fewer than 3 branches.

I am particularly good at: Production, development, marketing, communication, IT, sales, finance – frankly, I’m actually good at everything!

Me in one sentence: I produce STIHL components and products for professional applications.

My production family is this big

I have siblings in Fellbach, Weinsheim, Ludwigsburg, and Wiechs am Randen. We each have our own strengths. Fellbach is an absolute mathematics and computer genius and always the first call when it comes to finance and IT. Weinsheim is one of the most advanced magnesium die-casting plants in Europe. From Ludwigsburg, we are connected with the whole world, as it’s that location which ensures STIHL products make their way to the sales companies. Wiechs is the smallest member of the family, but a really high performer: It is where important components such as handle tubes and brush knives are produced. In total, more than 6,000 people work at all my locations in Germany.

Something I’m proud of: STIHL Brand World. In case you don’t know it already, it’s always a great place to visit 😊.

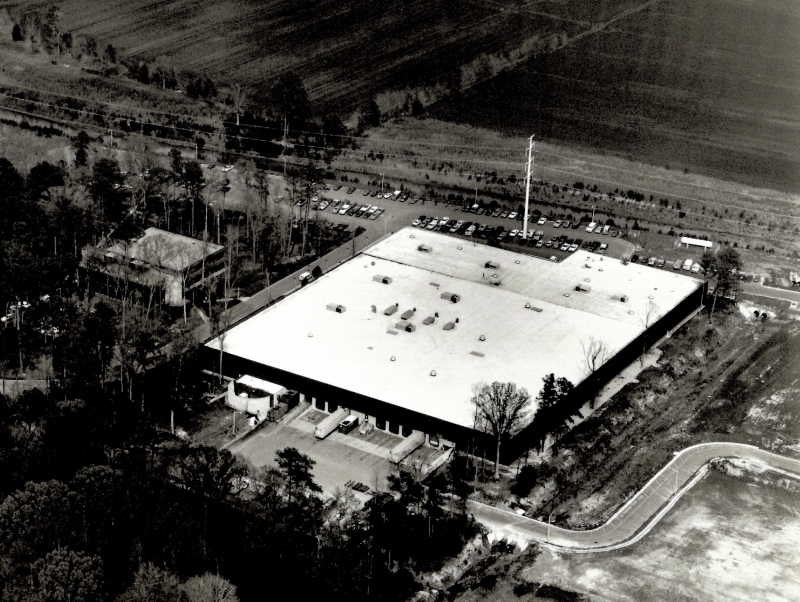

And that’s how I used to look in 1960.

My new administrative building in Virginia Beach was inaugurated in 2019.

USA

This is me: STIHL Inc., howdy!

I live here: Virginia Beach in the US state of Virginia, less than ten miles from the ocean.

How long I’ve been here: Since 1974. I started out making just one single type of chainsaw back then. Today, I produce more than 275 model variants, guide bars, pistons, and numerous plastic parts. I have produced 100 million product units. In 2024 I celebrated my 50th birthday.

What makes me stand out

I am the largest production facility of the STIHL Group, with an operating area of 1.6 million square meters. I think big in other ways too: I specialize in high volumes with short lead times. My production facility sets the benchmark for automation. Around 2,700 people work here. And for plastics production I process 16 million kilograms of granulate every year – turning it into tool housings in unmistakable STIHL orange, for example.

Something I’m particularly proud of: The US is another place that has huge potential for battery-powered products. I heavily invested in battery production in 2024, and I am doing my part to ensure we establish a foothold in this growth market.

Me at ten years old: A view of my production site in the USA, 1984.

I am always looking out on the Brazilian rainforest. No doubt that is one reason why sustainability is so important to me.

Brazil

This is me: STIHL Brazil, bom dia!

I live here: In São Leopoldo, southern Brazil.

How long I’ve been here: Since 1973. That makes me the oldest and first STIHL production site outside Germany.

What makes me unbeatable: Nothing happens in cylinder production without me. You’ll find my signature on 90 percent of all STIHL cylinders.

Something I’m particularly proud of

Approximately 3,000 people trust their professional life with me. And I love to go above and beyond for them – I have been recognized multiple times as one of the best employers in Brazil. Promoting and embracing diversity in the workplace always comes naturally to me: Equality and inclusion are important for a positive working climate. That’s super-important to me.

Something surprising about me: My sustainable use of resources really sets me apart. For example my energy efficiency program which was launched in 2014 has already saved 36,993,000 liters of water.

I was built in the early 1970s, in São Leopoldo, Brazil.

A modern look: In 2021, I celebrated the opening of my new entrance building in Wil with a cafeteria.

Switzerland

This is me: Grüezi, I’m the STIHL chain production site in Switzerland.

I live here: I have two home locations, both in the canton of St. Gallen – in Wil and Bronschhofen.

How long I’ve been here: Since 1974; I had my 50th birthday in 2024.

Me in one sentence: I am another representative of the renowned Swiss precision engineering – my specialty is not watches, but STIHL saw chains and hedge trimmer blades.

My family is this big: Around 900 people in total are employed at my two sites.

Something I’m particularly proud of

I equip our customers for every use case, because in my two chain production sites I produce 70 types of saw chain and over 40 different hedge trimmer cutter bars. Speaking of precision: To ensure the saw chains are durable, I harden each individual rivet (which holds the chain together) using an induction process.

“The largest chainsaw manufacturer in the world” will soon begin production in Switzerland – that was the announcement on a construction sign at my production site in Wil in the early 1970s.

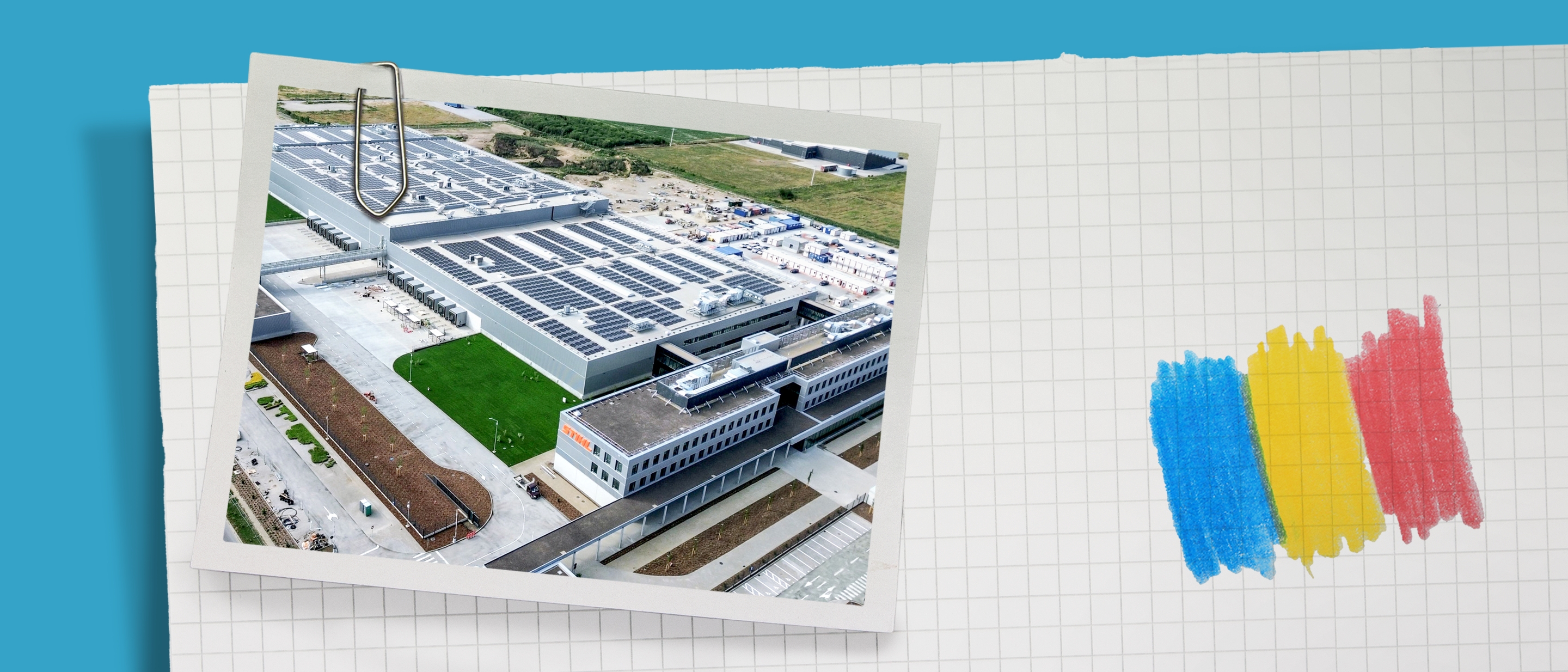

Pretty big: My 47,000-square-meter production area from above.

Romania

This is me: The new kid on the block in the STIHL production network: AKA the European center of excellence and manufacturing for battery packs and battery-powered tools.

I live here: I’ve just opened – on October 16, 2025 – in Oradea, Romania as the first STIHL production site solely specializing in battery power tools.

What I bring to the family: A production area of 47,000 square meters. By 2028 I expect to have annual capacity to manufacture up to 1.8 million battery packs and 1.7 million battery power tools.

What motivates me

I am strengthening the position of STIHL in the rapidly growing battery segment and championing the transformation of the industry. By 2035, 80 percent of STIHL power tools sold will be battery-powered.

My future goals: I don’t just want to increase capacity, I also want to employ more people. There are currently 135 people working here, and by 2028 there should be around 700. I’m really looking forward to that, because I hope to be a place that people love to work at and somewhere they stay a long time – all in a future-focused environment too.

Something I’m particularly proud of: I was certified with the Gold Standard by the German Sustainable Building Council (Deutsche Gesellschaft für Nachhaltiges Bauen, DGNB). During daylight and with favorable weather conditions, the site is capable of fully meeting its electricity needs from its own renewable energy generation. My roofs are greened and more than 250 trees have been planted on my factory grounds, which span a total of 147,000 square meters.

It came together quickly: My construction work began in March 2024 and was completed in just under 18 months.

Best mountain view: As STIHL Tirol I am based in tranquil Langkampfen.

Austria

This is me: STIHL Tirol, the center of excellence for STIHL ground-guided garden power tools.

I live here: Langkampfen, Servus!

How long I’ve been here: I was founded in 1981, though at that time I was still in Kufstein and went by the name VIKING. I was adopted in 1992 and became a wholly owned STIHL subsidiary. Since 2018 I have also taken STIHL as my name. And now I’ve turned completely orange – all my products are sold exclusively under the STIHL brand.

I’m really good at: Battery-powered ground-guided garden power tools – as we describe it in the STIHL family’s specialist jargon. In 2025 I was again recognized as an “Outstanding Tyrolean Training Company.” So in good conscience I can say that I am an attractive and responsible employer. My “We are inclusive” seal of approval also vouches for me in that respect. And have you seen the mountain panorama I work in front of?

My superpower

I ensure interference-free technology by examining the electromagnetic compatibility (EMC) of products before they go on the market. I do that for the entire STIHL Group in the lab I operate.

My favorite numbers: 98 percent of my products are exported out into the world. In my AutoStore warehouse there are 26 agile robots in use, handling more than 67,000 containers. Of course, I am particularly proud of my 900 or so employees.

Before I turned orange I was green, and they called me VIKING; the factory in Langkampfen opened in 2001.

One of my locations in China: STIHL Powertools in Qingdao.

China

This is who we are: STIHL Powertools and ZAMA, 你好 (nǐ hǎo)!

We live here: In Qingdao, for one. I’m also based in Huizhou, Hong Kong, where I go by the name of ZAMA China.

How long we’ve been here: I was founded in Qingdao under the name STIHL in 2005, and then integrated into the STIHL production network in 2006. I have been producing in Huizhou as a wholly owned subsidiary of the STIHL Group since 2017, under the name ZAMA.

What sets us apart

Qingdao is the second-largest STIHL production site after the USA. Since being founded I have produced over 28 million production units – primarily for the entry-level segment. I am also responsible for the assembly of chainsaws and power tools here. In Huizhou I operate under the name ZAMA as the world’s largest manufacturer of membrane carburetors and injection systems for small engines. I produce 9 million of these units annually in China.

Something we are particularly proud of: In total more than 2,300 people work in production for STIHL and ZAMA in China. And they truly enjoy their work: In Qingdao I was certified as a “Great Place to Work” in 2022. Employees there benefit from modern relaxation areas as well as a yoga and fitness room, and as such a more mindful working environment.

One of our specialties: In Qingdao there is one product I manufacture exclusively for the Asian market, which is primarily used for harvesting tea: The STIHL HS 52 hedge trimmer.

I manufacture under the name ZAMA near Hong Kong.

Production site behind palm trees: ZAMA Philippines.

Philippines

This is me: ZAMA Philippines – and even though you can’t tell from my name, yes I am a wholly owned subsidiary of the STIHL Group and have been fully integrated into the STIHL manufacturing network since 2022.

I live here: In Santo Tomas, not far from the capital Manila.

How long I’ve been here: I celebrated my opening in 2016.

I’m really good at: Carburetors for STIHL handheld power tools. I’m so good that I produce 6 million of them every year. I also manufacture electronics for battery-powered tools and battery chargers.

Something I’m particularly proud of

I am a key piece of the STIHL battery strategy – in 2021 I teamed up with the Elrad International Group to form a joint venture for the manufacture of electronic assemblies. I use my in-depth expertise in battery technology to make STIHL fit for future innovations.

My favorite number: I employ around 1,000 people here in Santo Tomas.

We are ZAMA: My employees are also creative outside of production.

STIHL Manufacturing Friends

STIHL Manufacturing Friends

For each question, select your preferred answer. You’ll find out immediately if you’re right or wrong. Good luck!